A simple, autonomous monitoring solution

The standalone SKF Machine Condition Indicator (MCI) gives plants a reliable, affordable way to monitor non-critical machines. It is ideal for machinery with constant operating conditions not previously monitored in plants. A vibration sensor and an alarm indicator in one unit, the fully sealed, battery-powered MCI requires no wired or wireless connections, installing directly on machinery for permanent installation for periodic measurements.

Much like the Check Engine light in a car, machine condition lights on top of the MCI

become illuminated when the unit detects developing issues, alerting maintenance

technicians that the machine needs to undergo a Root Cause Analysis. Three LED

lights rotate and blink green, amber, or red at various intervals and durations to indicate mode or alarm status.

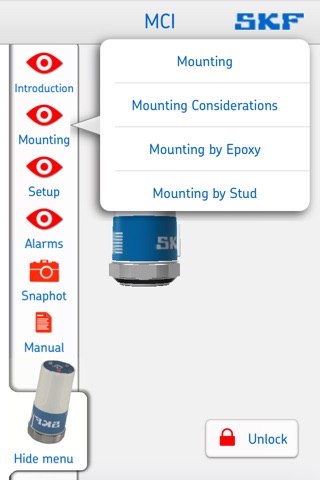

This app combines augmented reality to trigger and view an augmented 3D model of the MCI, and combines this with full operating instructions and animations to help users interpret alarm condition alerts.

Benefits

• Monitor non-critical machinery cost-effectively

• Extend maintenance route intervals

• Cut maintenance demands and costs

• Free up maintenance staff for higher level/other tasks

• Integrate MCI units into an ODR program/maintenance routes

Applications

• Non-critical machinery in plants with constant operating conditions

• “Standard” machinery running at steady speeds from 900 to 3 600 r/min

• Safe-area applications

Download the target image you need for the augmented reality function from: SKF.com / MCI